Two weeks ago, my colleague Ainhoa mentioned the idea for this post. The chance to recount my factory-floor adventures and experiences from the other side, now that I work at Safe, promised an exciting article. So, I grabbed my tea and logged onto Perplexity to gather the necessary info for a "learned something new, I'll check it at work tomorrow" moment.

After a few attempts, I felt a bit underwhelmed: many articles and documents list risks but lack clear data on why we should prioritize some over others. On one hand, it's logical; they're called invisible for a reason—a phenomenon similar to trying to measure the size of the underground economy or the trade of certain substances (a topic that will resurface in this article). Regardless, if we want this read to be useful, we need some rough numbers to evaluate and prioritize which risks and solutions affect us most. So, after MANY hours filtering through more than 50 publications, papers, and government documents, we have a global view of how the sector addresses this issue. Let's go!

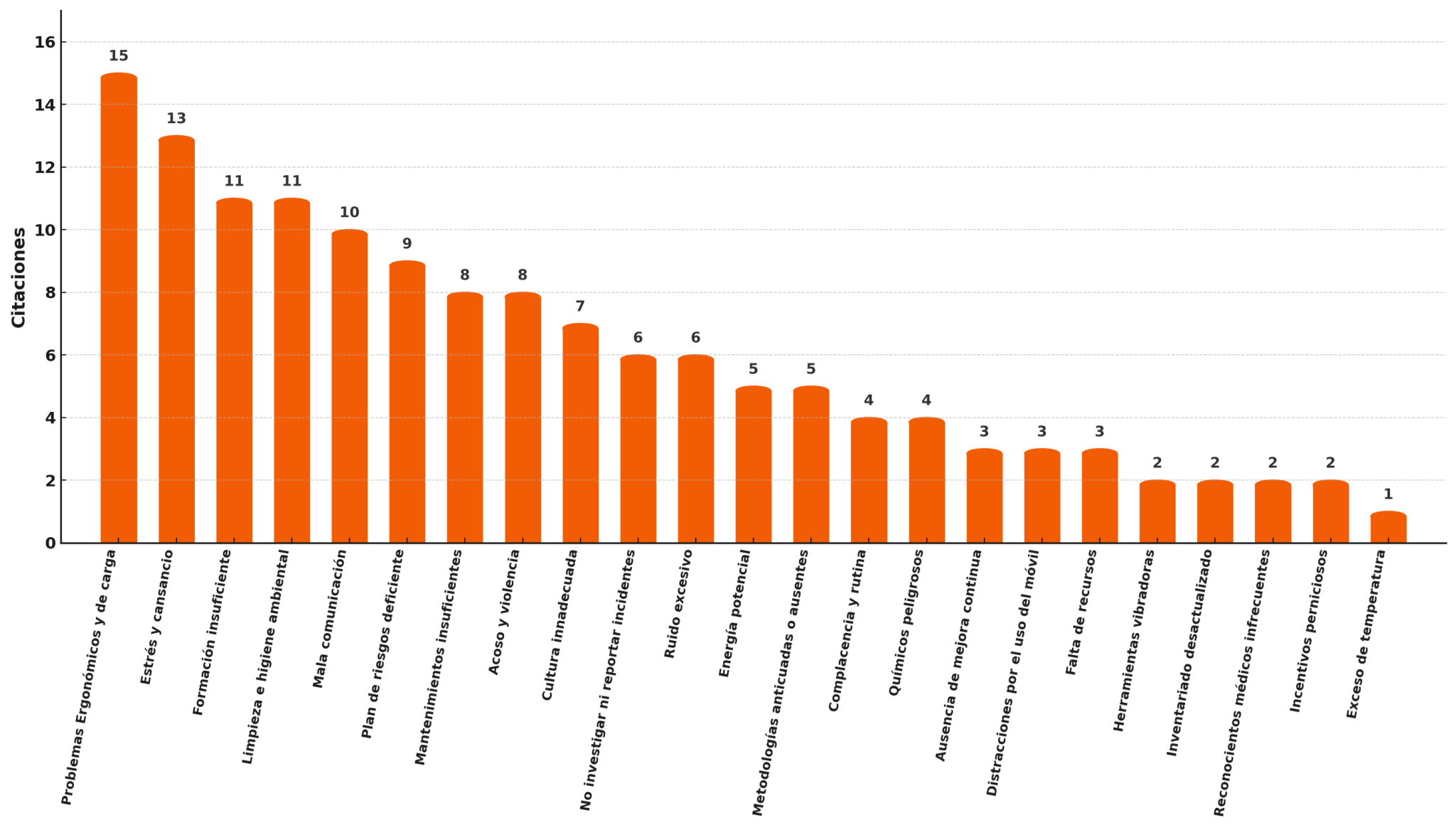

Getting to the point: which invisible risks are talked about most?

We've added them up one by one every time one of the articles in our references document cited a hidden risk, and we've represented them in this chart, from highest to lowest, to see which ones concern experts most. But let's not stop at the number—let's look for an explanation for the most significant ones:

Hidden risks related to ergonomics and loads:improper movements that are never noticed, excessive machinery vibrations known only to the operator, which in the long run translate into chronic injury. Surprised? I'm not. In almost a third of the articles, these types of overlooked actions are the ones that garner the most attention. On one hand, many of you already know OSHA, which highlights these risks as some of the most critical. If we need more proof, we just have to look at the official State bulletin: falls, poor movements, and heavy loads are the leading factors in accidents.

When you add the economic factor—since sick leave caused by these actions compounds current absenteeism and labor shortages—you get a combination that demands our attention.

Stress and fatigue:Boom! I admit I didn't expect so many references, following very closely behind the leading factor. It makes sense, as any task is affected by them, and risk conditions requiring high precision with no room for error or distraction can become the fundamental element. A very interesting point in this article is that biases in evaluating some risks over others often cause this factor to be overlooked.

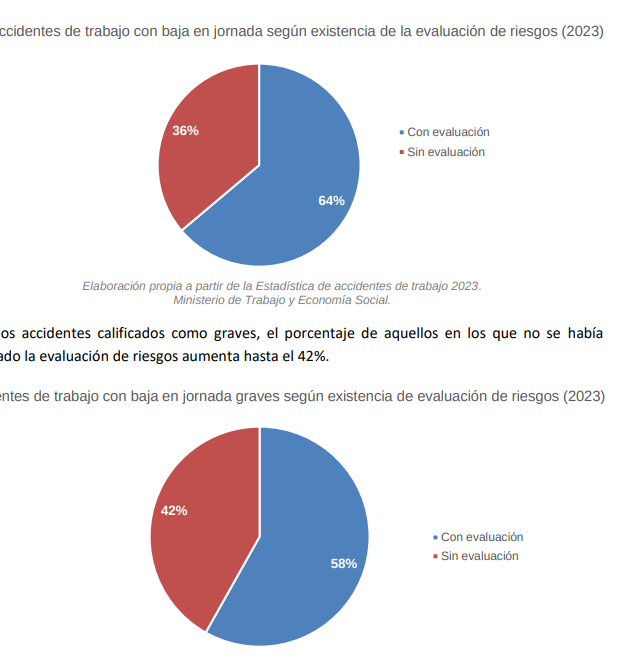

Insufficient training:if I may, we will analyze this factor alongside others that often go hand-in-hand: poor communication, deficient prevention plans, and an inadequate corporate culture. Most articles group them together, and it's no coincidence: in many cases, they are written by companies working in these fields, which, while it might slightly bias the perspective, also provides direct experience from the ground. Now, let's get to the basics: conducting a risk assessment is mandatory in Spain. Even so, more than a third of accidents occur in companies that haven't done one. How can this be? This data alone tells us a lot: a lack of resources or the will to invest in prevention can end in an accident. Often, it's simply because no one feels truly incentivized until it's too late.

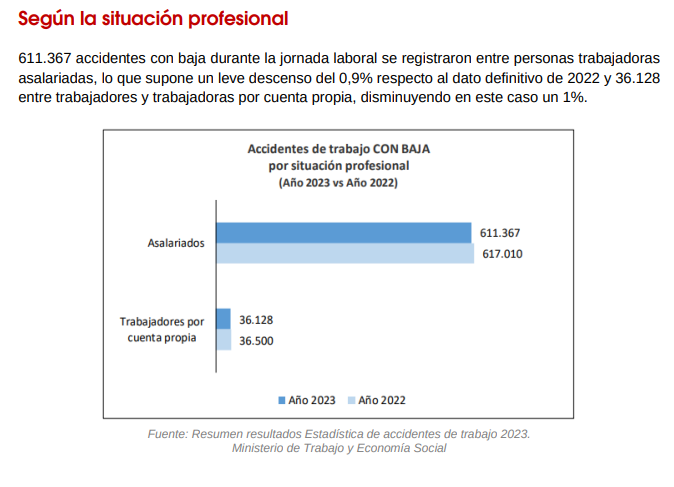

Corporate culture incentives are key. On a trip with a friend, he mentioned how many minor plant accidents weren't recorded to avoid administrative headaches or social security penalties, which completely hides the effects of our actions (this deserves its own article, but we can recall the classic and controversial risk pyramid). We can all see this in self-employed acquaintances. Seeing that they "get sick" 20 times less often than their salaried counterparts, it's clear that culture can indeed mask many sources of risk.

Lack of cleanliness, order, and environmental noise:again related to OSHA, with a clear link to, for example, falls due to oil or impacts in low-light or noisy environments that mask machinery; not to mention hearing injuries which, as with the first case on the list, can lead to irreparable damage over the years🙁

Harassment and violence:a very significant figure, which also inevitably leads to the stress we mentioned. It's frightening, but it makes perfect sense. Unfortunately, I've known people who have lived through these situations, and it's hard to understand how someone can fail to realize the double risk they impose on a colleague and how easily things can spiral out of control. What's most infuriating is that sometimes this risky situation is hidden because the direct solution—firing the employee who harasses colleagues after several warnings—is not executed, whether due to cost or personal relationships, leaving the victim to abandon the company to avoid further misfortune.

Surprises

It's not my intention for my personal life to outweigh all the articles we can review here, but don't you find some important hidden risks missing? I do, and even if I'm mistaken, I believe they are so common they deserve a mention.

Alcohol and substance use: call me crazy, but I don't understand why it doesn't appear. I've been lucky enough to enter nuclear power plants, where it's always said that safety is the first thing sold, even before energy. And what do we find at the entrance? A substance check. I'm not saying we should put this in every workplace, but a colleague once saw a worker raise a toast to his new boss when told he couldn't drink that beer on the job. Can you believe it?

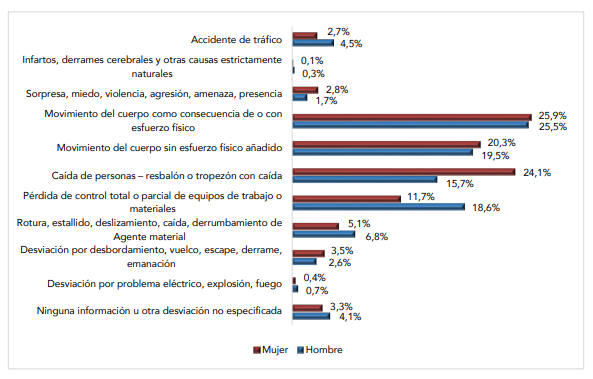

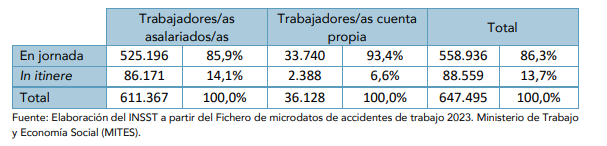

High speed or lack of maintenance while commuting (in itinere): for those who don't know, this is when you suffer an accident on your way to work, and it's classified as a workplace accident, even if it's in your own car. As you can see in the data fromUGT,they occur with excessive frequency considering how little they are discussed. Perhaps this case and the previous one are cited less because the actions are more complex? What I'm sure of is that training and awareness are key, something we already saw linked to culture and communication in the previous chapter.

Extreme temperatures: I still remember the foolishness I committed, taking a colleague under my charge to work in over 40ºC sun for 8 hours (I can't say it was more) during a drought. What happens when we take this lightly? Accidents like the one from a few weeks ago, which was in all the newspapers, should remind us that temperature is a vital risk factor: heat leads to dehydration, and cold causes numbness when using tools. How is it only mentioned once?! No, no, and no!

Mobile phone use and smoking on the job: I partly refuse to call it hidden because we see it every day, even if people try to hide it. Especially mobile phone use—I see it affecting everything: commuting, machine operation, tool usage... taking a call and not seeing a pit before falling in. That it's not the top concern gives me some faith in humanity, but that it doesn't appear at all, when again, we all see it, is unbelievable. And it's only going to get worse.

And why do I want to know all this?

Have some points in this article surprised you? Do you feel others are missing? What we've learned today should help us keep aligning our protocols and actions with real safety, showing our colleagues that our concern for their safety is sincere (we're fully committed to their well-being), as we continue to reduce the impact of accidents, injuries, and fears at work, with all the human and economic impact that entails.

Below, I'm leaving you a document with the sources we analyzed. Above all, I encourage you to write in the comments about the hidden risks you see in your day-to-day. Let's improve together🙂